Katsu, can I ask what your favorite Momotaro jeans model or fabric is?

K: Hmmm…there’s a lot of them, but lately I’m really liking this slim tapered I’m wearing now.

Nice fades.

K: Thanks…Momotaro tapered.

What’s the best part about doing what you do? The funnest part of your day.

K: Mmm, for me it’s spreading the word about Japanese denim, Okayama denim, Momotaro. When people in any part of the world say like, “I love your jeans” or “I love Japanese denim”, I think that’s the nicest thing for me. And I enjoy bringing that to people as well. Because it wasn’t always like that you know…at first nobody knew what it was or what we were about so…yeah it’s great now to see people happy with what we are making.

H: For me it’s still the act of making things. The pure excitement of creating something new, hoping it will go over well, but not knowing for sure…I love that.

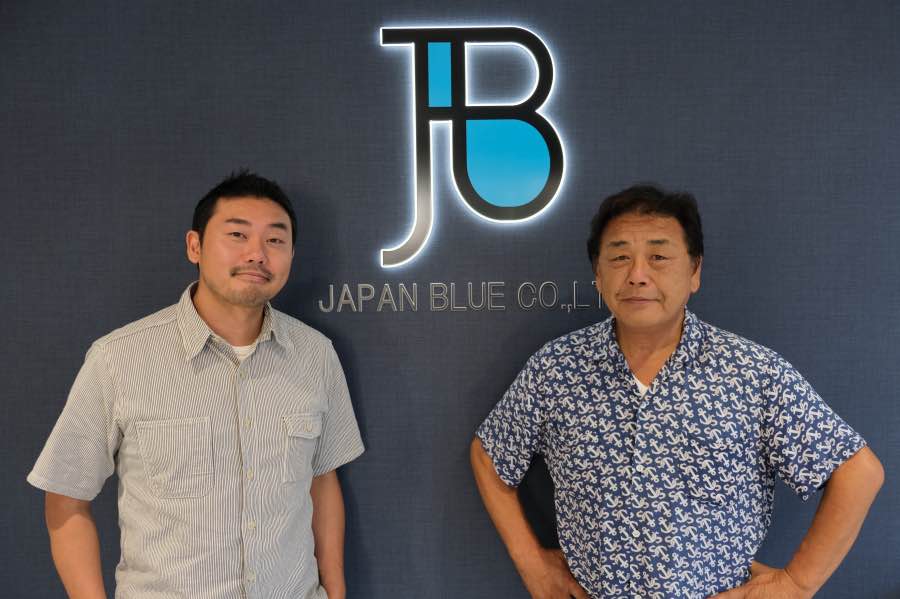

Photo courtesy of Japan Blue

And you knew the opposite question was coming – what’s the toughest part about what you guys do?

K: Well I’ve been saying how great it’s been these past ten years spreading the word overseas about Okayama denim and Momotaro, and now people know and like our stuff, but I do worry about, like say in 10 years from now, how are things going to go? Are things going to be fine if we just continue as we are, or are tastes going to change and we’ll get people wanting a bunch of different things from us? It’s hard to say. But I wouldn’t really call this a “worry” exactly though…it’s more just something that we can’t see at the moment. What’s the best way for us to survive and do well into the future?

Hisao-san?

H: As you might imagine, all the business end of it is tiring. Calculation and management. Managing different types of people isn’t easy.

K: And it’s not just us, it’s industry in Japan in general. In the States you have a minimum wage that is sometimes raised, but here minimum wage is still low and, you know, not so many people want to work because of that. Going forward, I think we need to change the overall system here somehow.

So aside from work, what do you guys do? What makes you happy?

K: For me it’s definitely traveling! (laughs)

H: It’s the same for me…we’re the same in that.

K: I was living overseas for a really long time so…in Paris. I’ve just moved back to Japan recently, but still I’m always away on business trips. To be honest, I don’t know that much about Japan because I’ve been gone 10 years! (laughs)

Really? (laughs) I’ll show you around, teach you some things then…

(all laugh)

K: Please, yeah. That would be great! (laughs)

Okay. So I know this is hard for some people, but how would you describe yourselves? What kind of person are you?

H: You mean my personality? I’m really kind of “whatever”, meaning like rough or approximate, you know, kind of loose. But then I’m also really careful and detailed in other things. Rough and subtle. I’ve got both of these things going on, two different sides depending on the situation. I’m pretty optimistic too I’d say.

K: Mmmmm, I really love new things. I think I’m curious and optimistic…probably patient too. I do tend to get lonely sometimes though, so I like having meetings, meeting new people.

Photo courtesy of Japan Blue

Hisao-san, can I ask you if you think the whole denim boom of 20-25 years ago is well-and-truly over? Where is the industry as a whole headed in your opinion? Up, down, or about the same?

H: Well, I don’t think blue jeans themselves are going to go away any time soon, but in Japan at least, you know we have pretty serious depopulation so…it’s not so much that the percentage of people here who love jeans is going down, more that the population overall is decreasing. And of course compared to the denim boom you’re talking about 20, 25 years ago, yes, the number has gone down. The fashion world is like that, but I also think that there is also a solid base of jeans lovers in Japan that isn’t going anywhere. And if you’re talking worldwide, there are of course a ton of people wearing jeans…they say maybe even 2 billion…and I don’t think that’s going to change.

I want to ask about your 10-year guarantee. That’s kind of unheard of for a clothing item…can you talk about that? When I tell my friends who aren’t into denim that my jeans have a 10-year warranty, they’re like, what?! Yeah right…

K: Haha…yeah, well of course if you go and tear a big hole in them, that’s a separate thing, but yeah, for accessories and bits that hold the jeans together (buttons, rivets) we’ll totally fix those for free.

H: Stitching too.

K: Yeah, that’s right. If the stitching comes unraveled we fix it. We just charge if there’s some extraordinary damage, like I mentioned, a huge rip in the fabric.

H: But Levis was like that in the beginning too. Built for life. It’s the same spirit.

K: True, back at the very start. Guaranteed for life. Maybe it was a kind of marketing strategy, but still, they were built in that spirit, in that they were meant to last.

H: You know the logo, right? Even two horses couldn’t pull them apart…(all laugh)

K: I’m not sure there’s anybody who has actually worn a pair of Momotaro’s for ten years straight yet but…

H: Just wear them with pride and care, like they were built: with pride and care. Just enjoy them and if they need fixing, we’ll fix them. It’s not just about numbers or years, it’s about community with our customers. That’s a big part of it.

K: Yes. We are also interested to see what the jeans might look like in 10 years. We want the customers to also feel comfortable being able to think like, “I wonder how these will turn out years from now?”

And all your jeans are made from Zimbabwe cotton, is that right?

K: For Momotaro, yes. For Japan Blue we use cotton from several different places.

Why did you choose Zimbabwean cotton?

K: For its long staple and its ability to take dye. And how the color manifests itself with Zimbabwe cotton. This is a bit hard to explain but…(uses his fingers to demonstrate staple length and weaving). With spinning you’re basically twisting together or connecting the cotton staples with each other, and with a longer staple there are less connection points in the finished threads so they are stronger. Good for dying, softer, and also the shiniest cotton we’ve found.

This might be hard for me to explain perfectly in Japanese, but there is a lot of talk these days about being ethical and sustainable, and there seems to be differing opinions on the ethics of using Zimbabwe cotton. Some feel it’s supporting a developing country, but others say you could be supporting an oppressive regime or dangerous working situation by using Zimbabwe cotton. Do you know what I mean?

K: I know what you’re saying for sure. If you just hear the word “Zimbabwe” or just look at the surface of it (or even just the popular reputation of it), yes, peoples’ image is of a poor country. Or people say that fair trade hasn’t taken root there, but in our case we have taken pains to ensure that what we do is fair and ethical. We’ve chosen one particular supplier and have worked with them for many years because they do engage in fair trade practices. So on the ground in Zimbabwe, there is no actual problem with what we are doing, but even still…in Europe when I say “Zimbabwe” people don’t exactly start smiling. Instead they say, as you pointed out, “But isn’t the government bad there? Aren’t they taking money from the common people?”

Hisao-san, what do you think? Zimbabwe cotton is the best for what you’re doing?

H: Of course every country, including Zimbabwe, has their own unique issues. We tried Zimbabwe cotton way back when and loved it for what we wanted to do, for the reasons Katsu explained: the long staple, the softness, the sheen, the ability to take dye. Of course I can’t say if we’ll always use it or not, and with Japan Blue we also use cotton from all over the world, but for now, for us, it’s the best we’ve found. In textiles you really have to consider each thing you are making and then choose the right materials according to your needs in each situation, so it’s not like I’m saying “It absolutely has to be Zimbabwean cotton”…it’s just that it happens to be the best material for what we’re currently doing.

Photo courtesy of Japan Blue

I think the heaviest Momotaro denim you can buy in Japan is the 15.7oz? Do you have any plans to go beyond that, in terms of weight?

H: Well, within Momotaro itself, considering our own customer base…hmmm…you’ve already got other brands making heavy stuff, like Iron Heart, so for us I’m kind of thinking we don’t need to do that right now. But that’s just within the Momotaro brand. Within our textile business though, we do order make 21….24oz denim and ship it out. So yeah, Momotaro doesn’t use that weight of fabric, but we do make it and we do sell it.

I saw a nice-looking pair of 18oz Momotaro jeans online that I wanted, but when I mailed Momotaro they said they don’t sell them in Japan. Different stuff for different markets?

K: Yeah, those are a foreign version. We make Japanese versions and overseas versions. I think the 18oz is too heavy for Japan, for Momotaro anyway…we’re approaching Iron Heart weight with those.

One of the biggest complaints I see online about Japanese jeans is that the pockets are…

K: Too tight, right? (smiles)

Exactly. Like you can’t even get your hand in there or fit your phone in the front pocket.

K: I do hear this one a lot. In Japan, with young people anyway, they normally don’t put anything other than the four fingers of their hand in the front pocket. Jeans like the old Levis 501XX of course had bigger pockets, but now makers are focusing more on the silhouette and it doesn’t look good if the front pocket area is loose or baggy looking. We played around with moving the outside pocket rivet like this (shows on his jeans, moving the upper outside rivet further out towards the back pocket), but then you had the top of the pocket being too wide and drooping down at the front. In Japan, people didn’t want this look. In Europe and other places overseas there is also a worry about putting stuff in your back pocket, because of pickpockets, so that’s another difference…another reason why people in Europe want to put things in their front pocket. That idea doesn’t exist here in Japan. And then of course there is just the natural size difference in peoples’ hands between Japan and overseas. Taking all this into consideration we do actually have different pockets on some of our models, but overall, they’re quite similar. But yes, the pocket size is a big complaint we get from Europe, the States, Australia…

Any complaints about inseam length?

K: No. The jeans are so long to begin with so…we don’t hear complaints about that.

Next one is a bit of a personal question but how do you feel working right alongside your dad? Is it fun or…?

K: It’s fun. I know in general that working with family can be tricky…a lot of fear or expectation, you have to keep up the history, the family name, all of that. That’s would of course be hard, but my dad doesn’t say like, “You have to do this!!” or things like that. He would be more like, “Try it and see” instead of forcing me or scaring me into do something.

And Hisao-san, I guess it’s the opposite question. How is it to be working so closely with your son?

H: I often wonder if there’s another father-and-son team like us out there. I don’t know if it’s good or bad, but at least it’s working for us. Of course I want to challenge him to take on new things, and also I want to pass on all that I know and do to him. I think it’s a great thing.

K: We can’t just do the the same things as each other so…all we can do is just feel it out and go from there. To break it down simply, my dad’s specialty and love is craft. Mine is styling. If you can’t communicate the things you’ve made to people, you can’t continue to exist so we really have to keep working together to not only come up with new ideas, but also to translate them to the market. I think we’ve done a pretty good job of it so far.

Is there anything you’d like to add or say to all the Momotaro and Japan Blue fans around the world who will hopefully be reading this?

K: I want them to have fun. Have fun wearing denim. And not like “things have to be THIS way” or anything, but just as a natural part of daily life. I want denim to merge with peoples’ everyday life. That’s my personal wish and I hope people are able to do that with our stuff.

H: For me, we put our life and soul into making the best things we can and we will continue to do that and continue fostering the connection with those who love and wear what we make. I also want to keep coming up with new ideas and new things to create. We want to make beautiful things, but I don’t mean just the final product, but also mean the communication and relationships that go into and with those things we make. I want to keep doing this.

At this point we left the boardroom and Katsu took me to check out the sewing room and the fabric samples room. The sewing room was small and had maybe 4 or 5 people working away on jeans at various stages of production. The samples room was incredible – hundreds and hundreds of kinds of different fabric, including of course a lot of selvedge denim.

Are these people sewing all people that had an interest in jeans or….?

K: Of course yes, they are all interested in denim…you might have also seen the older person in there? That’s our sewing…well, I’ll say ‘master’.

K: Our headquarters used to be where the Momotaro shop is, on Jeans Street, but then we moved here. My dad and the vice-president wanted to build a big building, beside the ocean, so now we have these two buildings.

So, who comes here to see all this? Wholesalers?

K: No, the brands.

Ah okay…and you make material for a lot of brands?

K: Yeah. Nearly 800.

800? I didn’t know that.

K: They select through some trading companies, or sometimes direct… So now, Okayama denim is kind of a known thing, known for quality, so people now will be like, “This is from Kojima” or “This is from a specific place”, but before it was just generally referred to as “Japan Denim” so they didn’t really know where there fabric was coming from exactly. And from the other side, we didn’t actually know who was using our textiles. So that’s why we’re moving to direct visits by the brands themselves.

And this is all made here?

K: Basically yes. But sometimes if a customer wants something that we personally don’t make, like maybe nylon or something knitted, then we use other industries in Japan that we know well to make them. So not every single thing you see in this room is made here in Kojima. We sometimes ask these other companies to cooperate with us and make us custom-made stuff.

This is denim heaven…honestly, I just want to sleep here tonight. I had no idea that you guys made this many types of denim.

K: Yeah, anything with the selvedge edge is of course done on the vintage looms. The stuff without is done on more modern machines.

Do you think you’ll ever make heavier denim than this in the future?

K: Well, for us 18 to 20 is kind of our maximum…otherwise it just kills the machines. Heavy ounce means heavy yarn for the weaving so… Heavy is fine but we also need to consider comfort.

I’m jealous of your job.

K: Haha…well we just started off as a small company.

So if you’re not traveling, what is a normal day for you? Are you always here?

K: It depends. Normal stuff would be like checking emails, having meetings, dealing with orders, finding new things for us to make. But I’m always traveling. My wife is actually living in Paris, but she’s coming back to Japan today. I’ve been in Paris 10 years actually.

Well today has been amazing. I’m so glad I drove down. Huge thanks to you and your dad for being so open and welcoming.

K: Well thank you for coming down all this way.

I won’t drive next time so we can have a beer. (laughs)

K: Sounds good.

And there ended my wonderful afternoon in Kojima, talking with Japan Blue and Momotaro’s Katsu and Hisao Manabe.

You can check out Japan Blue and Momotaro’s homepage here.

Pingback: Momotaro's Hisao and Katsu Manabe, Part 1 - Japanalogue

thanks for doing these interviews!