It’s normally a 3 hour drive down to Kojima from Osaka, but I’ve somehow managed to do it in record time and now find myself poised outside Japan Blue’s headquarters a bit too early. No matter though as I head inside and try to find the man I’m looking for: Katsu Manabe, the son of Collect Mills, Japan Blue, and Momotaro founder, Hisao Manabe.

I encounter some helpful staff upon entry, and I’m soon ushered into a large office-slash-boardroom where the father-and-son duo are waiting for me. Katsu speaks English quite fluently, but we decide to do the interview in Japanese anyway so Hisao can understand as well. Before we know it we’re chatting away and laughing about all things Kojima, all things denim, and it soon becomes obvious that the large size their company has grown to has done nothing to dampen their enthusiasm for making jeans or for the beautiful area in which they live and work. I hope you will enjoy our talk.

What was your original aim or motivation back at the start?

Hisao: Well, to put it simply, it was to make Japanese denim the best denim in the world. That was my main goal.

And that started first with your own mill (Collect Mills), right?

H: That’s right. So at that time I was wanting to take Japanese textiles, Japanese denim, and make them the best in the world. I knew of course that in terms of the actual history and origins of denim, well, we can’t really compete with America or Europe on that score, but I was thinking that if we could take the Japanese spirit of quality and fine craftsmanship and apply that to making jeans, we could probably make jeans like nobody else in the world.

I probably should have started with this, but can I ask what you did even before founding Collect?

H: Before Collect I was in the dyeing business in this area from about 1986, and I was also involved in trading different textiles, fasteners, buttons, accessories, etc. Dealing with various companies all in this area. I did this for about 6 years.

Katsu-san, did you have any idea when you were young what your father was doing for work? Were you interested at all in it?

Katsu: At first, not at all. I just knew he was somehow doing something with denim…that was it. I didn’t know anything about denim other than I knew it was a fashion item, a vintage item. Dad’s business wasn’t the kind of business where you were just selling fabric to regular individual customers, so I didn’t really know or see what he was doing. But about the actual brands that were popular back then, I did like to read fashion magazines at that time so I was at least familiar with the famous names that were making jeans. So while I guess I was interested in some of the brands that were out there, I had no idea what denim or jeans meant as an actual job.

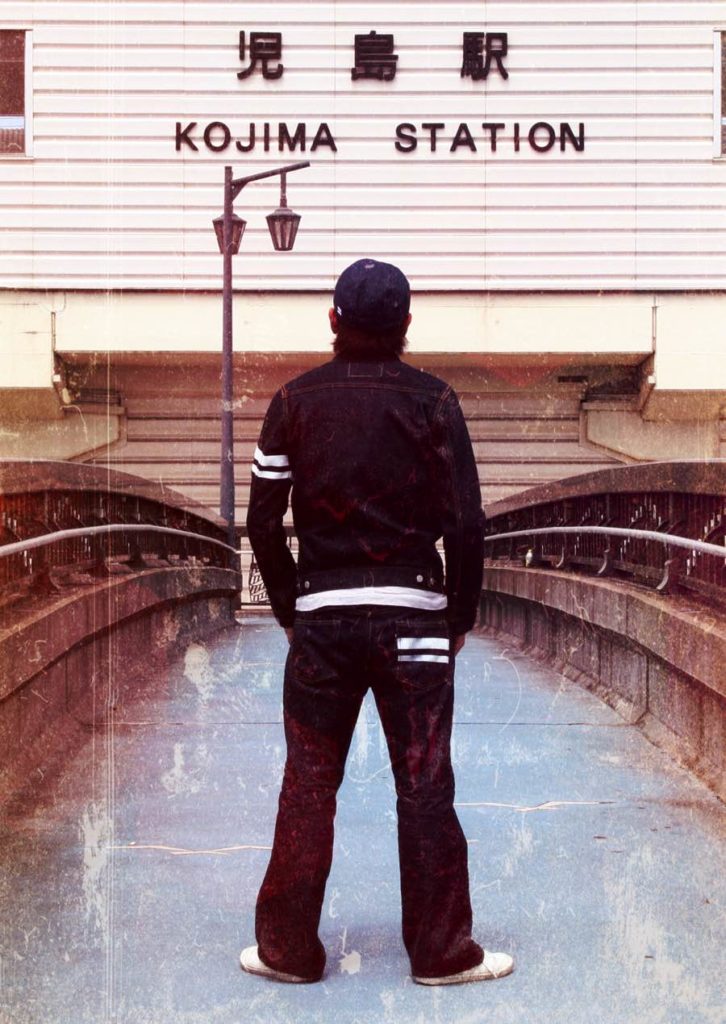

Photo courtesy of Japan Blue

So you weren’t thinking like, “I’m going to work for my Dad!”

K: No, no, no….(laughs)

Were there any challenges, setbacks, difficulties, etc. you had to face back then?

H: Yes, for sure. I had done many different kinds of work before I started with this and of course there were different kind of setbacks. I was 31 when I changed my job again and got into this industry, and went out on my own and established my company in ’92 while studying all I could about textiles. It wasn’t easy.

So I’ve read a simple explanation on the net somewhere about why you decided to have two separate brands: Japan Blue and Momotaro. Can I ask you directly why you did that?

K: Well the simple answer would be that we started with Momotaro – it came first. For the first couple of years we had nothing other than Momotaro. Japan Blue didn’t exist yet. At that time Japanese denim fans were denim maniacs, like completely nuts about all the little details on Japanese jeans like the hidden rivets, all the different stitches, etc. So when I went to Europe for the first time to try and sell our jeans, you know, people didn’t really understand or go for all of that insane detail stuff we were doing. And, you know, Japanese jeans aren’t cheap so…some people there were even like, “What is selvedge?” Such was the mystery of Japanese jeans back then. So we had to kind of go back to the drawing board, and we knew that it was our fabric that had always been our strong point, so we decided to focus on that, keeping the fabric quality as high as possible, but constructing the jeans in a bit simpler way than the usual Momotaro stuff. We then launched Japan Blue in 2010 for the international market, to produce jeans using the same high-quality fabric, but not focusing so much on all the intricate details in the construction. High quality, made simply.

I see. People didn’t even know what selvedge was back then eh. Wow.

K: It wasn’t like there were no Momotaro fans at all back then…there were, but there just weren’t that many of them (laughs). So overall it was tough back then because people would be like, “Hey, this pair of Dior jeans is $320 and your Momotaro jeans are also $320. What’s going on here? How are they different?” But it was hard to completely explain, you know, the history, the craftsmanship and time it takes to make our jeans. It was a bit of a tough place to start from, so we decided to create Japan Blue as well for the international market and go from there.

Was it kind of intimidating for you going overseas back then and trying to do all this by yourself?

K: Not really actually. I’m 40 now, but I went to live in Canada for a year right out of high school and was able to learn English, so I had that going for me even way back at the start. Then I came back to Japan and worked at my Dad’s friend’s company for a bit, but then went to Bali and lived there for two years where I was doing some production management work. I’ve always loved traveling overseas and speaking with all different kind of people so, yeah, I wasn’t scared. It was mostly fun, but of course there were some worries there as well.

Were you able to make good jeans right away once the company was established?

K: Mmmm…..no, not really. It took about 2 or 3 years to make something that really fit the market. I mean the international market. We started in Japan wanting to make the best materials to make the best jeans with the best fit, but when we went to Europe of course the body type is totally different, the average height of people, as were the styles that people wore so, yeah, that took some time to get that part right. It was a gradual process, but I literally went around store-by-store to ask questions and get advice on what might work, and slowly we were able to come up with the best fits we could. And with Japan Blue we put these fits into production with, like I was saying earlier, high quality fabric but using simpler construction.

This is probably an obvious question, but Japanese customers and overseas customers are quite different, aren’t they?

K: Completely different. The biggest thing is the difference in fits. Jeans are made from a material that shrinks of course, so we have production measurements and also sales measurements. Sales measurements are actually set by the shops and they can kind of be what you could call selfish or vanity measurements, whereas production measurements in Japan are totally uniform – an inch is always going to be 2.54 cm. So we’ve got this situation now where sizes around the world don’t really match each other, so you might be a 32 in Levis but need a 34 in our jeans kind of thing. So this is one thing we have to always keep in mind. About the fits, Japanese like a straight fit, wide…like the vintage Levis 501 cuts. Overseas, or at least in Europe, tapered cuts are the standard now, so that’s something we’ve had to adapt to.

Do most of the new ideas for Japan Blue and Momotaro come from you or…

K: Everything first started with my dad…Momotaro or what you might call our ‘first masterpiece’ (laughs). If you want to know how Momotaro was born in Japan I think you should ask him (laughs)…go ahead if you want…

Photo courtesy of Japan Blue

(laughs) For sure, for sure. Hisao-san?

H: Hmmm..well, you know at that time whenever I wanted to wear jeans it was kind of like I would think to myself that I didn’t have any jeans of my own, that I had made myself so…

K: (In English) He had so many textiles but didn’t actually have any products himself…and he made the best material in Japan for so many makers but didn’t make anything with it himself.

H: Up until that time, I had been supporting and supplying the best jeans makers in Japan, you know, everybody making their vintage stuff, but still I wanted to make something of my own. Of course we didn’t really know how to do that part of it, but we had been watching carefully on our trips overseas or working with the brands here we were supporting, so with all of this knowledge and experience in mind, I decided to create my own brand. Up until then I had been completely immersed in indigo dyeing and that end of it, so I figured why not just make jeans myself? And my intention wasn’t to make the coolest brand out there…it was to make something that was true to this area, jeans that were totally made here in Kojima. So I wanted to make a brand that represented the artisanal history of this area. But everybody here was against it, they said the name Momotaro was totally lame…not cool at all…(everybody laughs)

What? Really? Why would they say that?

K: (laughs) Yeah, in this area the name just seemed, like, way too obvious. It’s the first thing people think when they think of Okayama, the folk tale Momotaro. Everybody knows that Momotaro (the boy in the folk tale) is from Okayama. Okay, like how about Dave starts up a Canadian jeans company and calls it Maple Leaf Jeans? How’s that sound? (laughs) It’s almost embarrassing, right?

Ah, yeah…that would be pretty lame. (all laugh)

H: You know, the whole jeans thing here was based on the ‘American dream’ back at the start so…of course having a cool name is important. I get that part, but you never know how the future of fashion and tastes will go, so I wanted something that wasn’t going to lose its meaning as tastes changed. I wanted a name that was solid, something that would stand the test of time. So I went with the name Momotaro…even though people said it wasn’t a cool name, or you’ll never sell something with a name like that.

You know, I think that for non-Japanese the name is totally fine. It sounds quite cool in English actually.

K: Yeah, at the very least I think it’s unique and it has a certain impact outside of Japan, you know, people kind of wonder, “What does that mean?” And even in Japan, these days, you do see some other companies using local stories or characters to represent their goods so…the story of Momotaro is just from Okayama so I do think it’s unique in that way, even here.

H: I think it makes sense in the context of what we were talking about earlier, that I wanted to make jeans unique to this area, all made here and sell them around the world. Okayama equals Kojima equals jeans equals Momotaro, it’s all connected. It makes sense this way, right?

K: Yeah everybody knew that Okayama equals Momotaro, but not everybody was aware of the denim production in Okayama so we wanted to make that connection obvious. So we wanted to put the names Okayama, denim, and Momotaro together. For Japanese people. And overseas.

Doesn’t it actually say something like that on the little tag in the waistband of Momotaro jeans?

K: (laughs) Yes, that’s it.

H: At the start nobody really related jeans with Okayama, that image didn’t exist in the world so we started with that in mind, to bring together those elements in the minds of customers: denim, Okayama, Kojima. I think it’s really just in the last 20 years that the world really knows about Japanese denim…before that nobody really knew what it was or what area it came from.

Photo courtesy of Japan Blue

I see…

K: Yeah, it’s unique. It’s like Levis used denim from White Oak in the States…from Cone Mills. Nobody really knew where White Oak really was you know, just an industrial area. Now the mill is gone and people don’t remember the place. We want to put it all together in peoples’ minds, the jeans, the production, the place. We wanted to revive Kojima as a production center, have things made here again, have people come. That’s our wish.

H: We spent a lot of time supporting all the vintage makers so we had some experience, some confidence in that…and I got into this when I was 31. But I’ve done a lot of different things, it’s almost like I’ve lived a few different lives. I know this is kind of changing the subject but…

K: He’s done a ton of different things before the textile business.

H: (shows a kind of pictorial diary showing all of his different jobs). I was a civil servant, I was a cafe owner, I was a gardener (laughs). So my point of view is a little different from the average person I think…

K: He’s seen the world through several different sets of eyes.

H: So I was wondering what would be the best thing for me to do and I found it was to make things, to create things. And I think Japanese people can produce very high quality items, so it was with this in mind that I started all of this.

K: I’ve done a lot of different things too but not as much as my dad. I’m not sure I’ve met anybody that’s done what he’s done…he started at city hall, then to gardening, worked at a pub, then into construction…he was even a driver.

Wow, you’ve had a rich and varied life already. Lots of ups, lots of downs?

H: Yes, plenty of those. (laughs)

I got this book the other day from Amazon, one of those yearly Japanese Denim kind of “bible” things and it was saying Hisao-san was the King of Jeans Street. Did he actually create Jeans Street or how did all of that start?

K: Yeah, he made it.

Can you tell me about all of that?

H: Kojima used to be a busy, bustling place with full shopping arcades, but slowly the population began to fall, shops had to abandon their businesses and close, and you had all these old, shuttered places lining the streets. So we knew we had to do something and we decided we wanted to make the best shopping street in Japan but…we needed a theme, something that would work for this area that people would be interested in. And we decided that thing was jeans. That’s how it all started. And then we had to go about getting or renting all these places so they were along the same streets, matching the denim companies to each place, and so on. And from there we just started to do everything around the area in the denim theme, right down to actually getting the train station’s name changed to Jeans Station.

Are you actually allowed to do that? (laughs)

K: It’s actually the only place in Japan where that’s ever happened. Even on the official signs in the station the subtitle is Jeans Station. (laughs)

H: It was then important for us get celebrities in Japan to wear Japanese jeans, to come here, to be on TV. We collected a lot of them and this became our PR because we didn’t have much money, so this was like free advertising. T.V., magazines, it was really important and a big help.

How many jeans companies were on Jeans Street at the very start?

K: At the very start there were just two: Momotaro and one other.

And how many now?

H: 37 or 38.

K: Yes, it’s taken about 10 years to get up to this point.

Sounds like it’s working.

K: Well the first year we had 5000 people come to Jeans Street. Last year we had 200,000.

That’s all from overseas?

K: No, that’s everybody, from Japan and from elsewhere.

Are there more foreigners coming than Japanese?

H: No, definitely more Japanese, but the number of overseas customers is steadily going up.

The next question might be tough, but are there any other brands or denim companies out there that you like or think they’re doing an amazing job with their jeans?

K: Hmmm….(thinks a bit)…other brands…

It’s okay if there aren’t any.

K: No, no, there definitely are…

H: For example, Haraki-san over at Iron Heart…you know, he’s a biker so he’s focused on making really heavy denim and things for that crowd and he’s doing really well. He also has a background in textiles so he has a lot of knowledge and knows what he’s doing. So he’s making good stuff for sure. But there are also lot of vintage makers, and I’m including Iwaya-san here (before the interview, the three of us were discussing Iwaya-san from PBJ, who doesn’t make vintage replicas but is a very respected and inventive jeans maker from Kojima) who are not only working really hard at what they do, but also being innovative. Basically all of them are really good. They’re all doing their best.

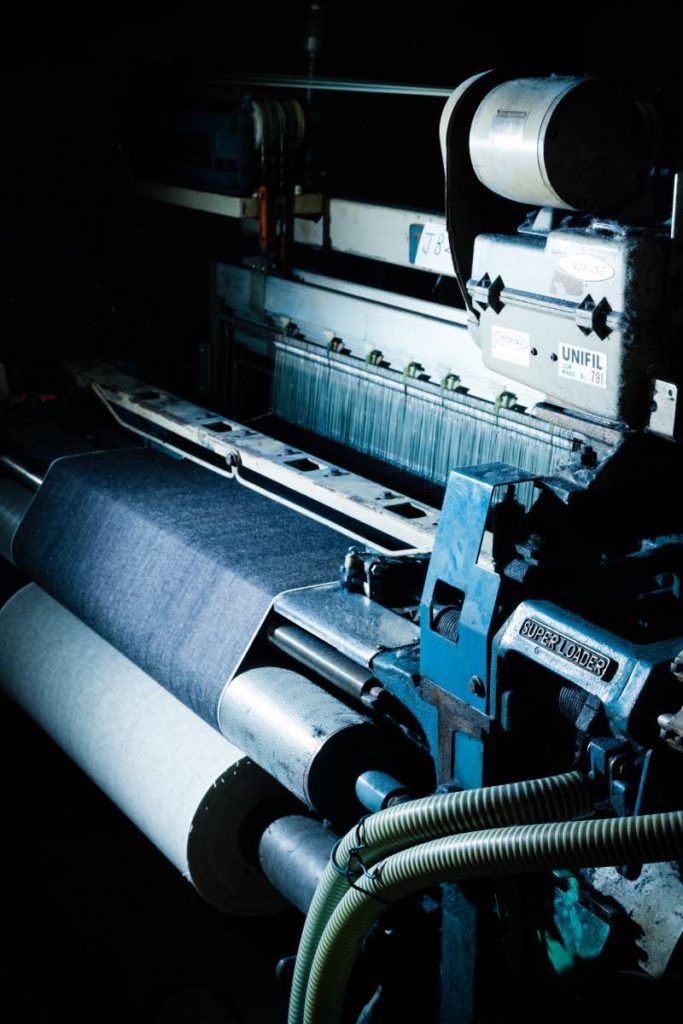

And you guys have your own looms, your own weaving mill. Would you be the only denim company that has that?

K&H: I think so, yes. That’s probably right.

Aside from you guys then, do you think there will be selvedge denim shortage in the future?

H: That worry exists for everyone, even for us. But we are taking precautions. We need to train young people and we are also going to move the mill closer to us very soon.

K: (In English) So we have a medium-sized weaving factory in the center of Okayama prefecture, about 30 or 40 minutes by car from here. We have 10 Toyoda shuttle looms there but we are planning on moving them all here. We are just finishing the building here where we will house the looms and we’ll be done soon.

What kind of looms are they?

K: Ours are vintage Toyoda GL-9s.

Where did you get them from originally?

H: From a shop that sold vintage looms.

What? There’s a shop like that? You just walk in and pick up a few vintage GL-9s?

(everyone laughs)

K: Dad, was there a place like that?

H: Back then there was…not now of course.

K: Okay…it seems there was a shop like that. (laughs)

Wow, that’s awesome. Can you imagine that now? What happens when they eventually break down?

K: We have some original machines set aside for parts so we just take what we need from there and then fix what needs to be fixed. We are also currently training a younger craftsman in maintenance and repair so…he’s able to do what needs to be done.

How about the sewing side of things? Iwaya-san at PBJ was saying that this is going to be the real issue in the future.

K: Absolutely, that’s also an issue. Aside from little specialist shops, there’s not many places left. It’s going to be hard for brands that don’t have their own factories because even if you put in your order, it could be a long wait.

Where is your sewing factory?

K: Ours is right here. But we also use several other small places that we have good relationships with but…if we have them just doing our stuff then other makers won’t have a chance to use them and we don’t want to take that all away from the smaller brands, so those sewing places do just some of our stuff and some stuff for the other brands. That’s why we also do some of it here.

I know it came out a few years ago now, but your dad had a part in that awesome documentary, Weaving Shibusa. How was it filming that?

H: It was kind of normal. (we all laugh)

K: Dad’s been on T.V. and in movies a lot of times in many different places so…I guess it’s just kind of natural for him. (laughs)

I thought that show was so well done. The cinematography, the music, it was great.

K: Yeah it was good. There were several roles in that so I think Dad took the one of the indigo dyer…probably because nobody else in the film was doing that so he wanted to do something different.

Photo courtesy of Japan Blue

Read part 2 here.

Can I buy a coat like this?

Top photo, Katsu